Although it is often declared dead, EDM clearly continues to live and has firmly established itself within manufacturers’ process chains thanks to advances in technology, including EDM automation, faster speeds, power supply and control units, wire threading, electrode materials, programming and software. Most companies’ exhibits at EMO 2017 in Hannover, Germany, this past September were themed “connecting systems for intelligent production” and had a strong focus on current manufacturing trends such as Industry 4.0 and energy efficiency. They also featured a range of dedicated products and a comprehensive portfolio of cross-technologies and intelligent solutions, which some companies claim will take users’ manufacturing processes to the next level.

That next level includes Industry 4.0 solutions, which highlight automation, monitoring, preventive maintenance, autonomous production, a real-time simulation as a digital twin, connectivity and cloud solutions using different open protocols. One eye-catcher that points to a likely Industry 4.0 infrastructure in the future was Makino’s iAssist, a collaborative autonomous robot solution that is mounted on an automated guided vehicle (AGV) and serves both tools and workpieces to several system-connected machines.

In regard to EDM, the exhibits at EMO were less about revolutionary developments than evolutions in machine design, software, parts handling, automation systems and data consistency. These evolutions are designed to meet five major demands from mold shops and their customers: higher precision, shorter lead times, reduced costs, greater repeatability and improved quality.

Machine Design and Thermal Stability

Innovations in machine design ensure thermal stability, and thermal stability enables machining with higher precision. To respond to the industry’s growing demand for that precision, OPS Ingersoll (represented in the United States by MC Machinery Systems, Inc.) has developed a new die sinking electrical discharge machine, the Eagle G5 Precision. “The limiting factor when it comes to accuracy is the ambient temperature, which varies in many shops and affects precision,” Matthias Schmidt, head of sales at OPS Ingersoll, says. “So, machine manufacturers integrate real-time active sensors into their machines to feedback changes in temperature and compensate volumetric errors.

The result is a new concept. A completely closed design minimizes the influence of temperature changes of the surroundings on the whole machining process. Schmidt points out, however, that the accessibility of the working area for automation or manual loading is not restricted. This is because the machine’s enclosure can be completely retracted into the machine base with the push of a button.

Schmidt says that high thermal stability is the requirement for absolutely precise results with a deviation below 5 microns, which makes the machine ideal for multicavity applications. Another development is the new and powerful Eagle Power Spark Generator, which features a small gap to produce the finest geometric details. “We produce fine, homogeneous and even dull shining surfaces, which could never be realized with graphite before,” Schmidt says.

The benefits of new generator technology become most apparent to those moldmakers producing complex components with intricate details. In some cases, these jobs require more than 40 electrodes to produce a single mold. If that number can be reduced by 25 to 40 percent with little increase in machining times, the potential for savings is tremendous.

Machine Design and an Evolution in Generators

Advances in the use of generators reduces costs, shortens lead times and improves quality. Other EDM suppliers are facing the same demands in increasing complexity and accuracy and, like OPS Ingersoll, have further developed their systems and generators. ONA (Vizcaya, Spain), for instance, specializes in special-purpose machinery. At EMO, it displayed a new digital generator featuring two heads to improve the productivity of moldmakers servicing the automotive industry. “As EDM is a rather slow process, moldmakers are often forced to look for alternative processes in order to stay competitive,” Marketing Manager Leire Gomez says. “Milling or high-speed machining is a much faster process compared to EDM. However, especially when it comes to machining very intricate details with very small internal radii, EDM is the process of choice.”

ONA developed the ONA TQX8 to meet the automotive industry’s demand for short lead times and to meet the growing pressure for less expensive tools, especially with competition from a global marketplace. The ONA TQX8 has two heads, which are independently controlled. The company claims that machinists can use them to simultaneously machine two separate parts on one machine, or they can reduce the machining time of the same component by as much as 50 percent.

GF Machining Solutions (Meyrin, Switzerland) developed the Agie-Charmilles Form S 350 die sinker, which is fitted with the company’s Intelligent Speed Power Generator (ISPG). According to GF, the generator makes it possible to use a smaller-than-ever spark gap to remove minute amounts of material to achieve very fine geometric details. The smaller electrical current that machinists need to machine cavities reduces electrode wear.

The growing complexity of many workpieces not only requires highly efficient generators, but automation solutions as well. Complex workpieces require automation solutions that enable the necessary frequent changeovers between machines, affecting timing and repeatability.

Automation Solutions with Robots

Combining several technologies with automation systems like robots and handling systems reduces leadtimes and improves quality. “Moldmakers are looking for solutions that combine several technologies such as EDM, five-axis machining, hierarchical storage management and in-process inspection and parts cleaning,” Jens Habenicht of German EDM and handling solutions provider Zimmer & Kreim says. “The ability to transfer parts across various machining platforms to reduce cycle times and minimize handling is increasingly in demand from mold shops in Germany and Europe.” The company’s chameleon linear handling system automates the entire production process right up to parts drying and cleaning.

An intelligent combination of high-speed milling and EDM often becomes a decisive factor in the race for on-time delivery, which Makino addressed at its booth. Makino’s iAssist cell is comprised of a D200Z five-axis vertical machining center connected to two EDAF2 sinker electrical discharge machines and a coordinate measuring machine. The process outlined the complete manufacturing process, starting with roughing on the D200Z to finishing on the EDAF2. Erowa Technology Inc.’s Robot Compact 80 connected the machining center with the sinker electrical discharge machine, featuring a maximum transfer weight of 80 kg (176 lbs).

Other solutions to automate EDM processes include robots and cobots such as Sarix’ SX-Cobot automation cell connected to the company’s electrical discharge machine. The cobot automatically changes heads for EDM hole drilling and micro milling for 3D cavities. The cobot integrates measurement technology such as touch probes or laser scanners into the machine by exchanging the work spindle for a measurement spindle. Moreover, Sarix’ micro EDM center Mach-Line features two Z axes, a micro EDM head and a measurement unit for in-process part inspection. Process combination on this twin-axis machine also works for complementary processes such as micro EDM and micro laser ablation.

Automation Systems on Minimizing Input Errors

Automation for the sake of automation can be problematic. To work, automation systems must guarantee consistent data deliveries to eliminate input errors. It is not as simple as installing a robot to enable lights-out machining, Schmidt says. “I have seen many shops in the United States that have automated their EDM process with a robot, but often the operator has to manually program each electrode position, which leaves room for error and is far from what we call Industry 4.0 or data-driven manufacturing.”

“In fact, with the rise of Industry 4.0, the most important consideration for manufacturers is the role that automation can play in streamlining their processes,” Schmidt says. “Streamlined processes cannot be achieved without data consistency. This means that data is automatically transferred from the CAD system to the machine and robot, reducing the probability of errors that cause delays and scrap.”

Streamlined processes cannot be achieved without data consistency.

As a result, many companies have developed enhanced and user-friendly software solutions. Erowa offers a complete process management system called MoldLine JMS 4.0 that features interfaces to enterprise resource planning and CAD and CAM systems to ensure direct data imports and feedbacks. Makino’s new EDM CAM software EDCAM 2017 automates many processes, such as creating and adding cavities from a 3D model, ascertaining all electrode positions, recognizing and calculating the spark area, recognizing and acquiring depths, finding measuring points and recognizing workpieces. Also, most machine tool manufacturers, cutting tool companies and software and control suppliers offer real-time machine process monitoring and data management software solutions that can be integrated seamlessly into third-party solutions supporting MTConnect or UPC-UA protocols.

The bottom line is that EDM manufacturers and suppliers have responded to moldmakers’ requests to improve their productivity. EDM has become faster and more efficient. EDM uses fewer electrodes and can achieve finer surface finishes without any polishing time. Automation systems that include intelligent, user-friendly software and data consistency increase unattended machining hours.

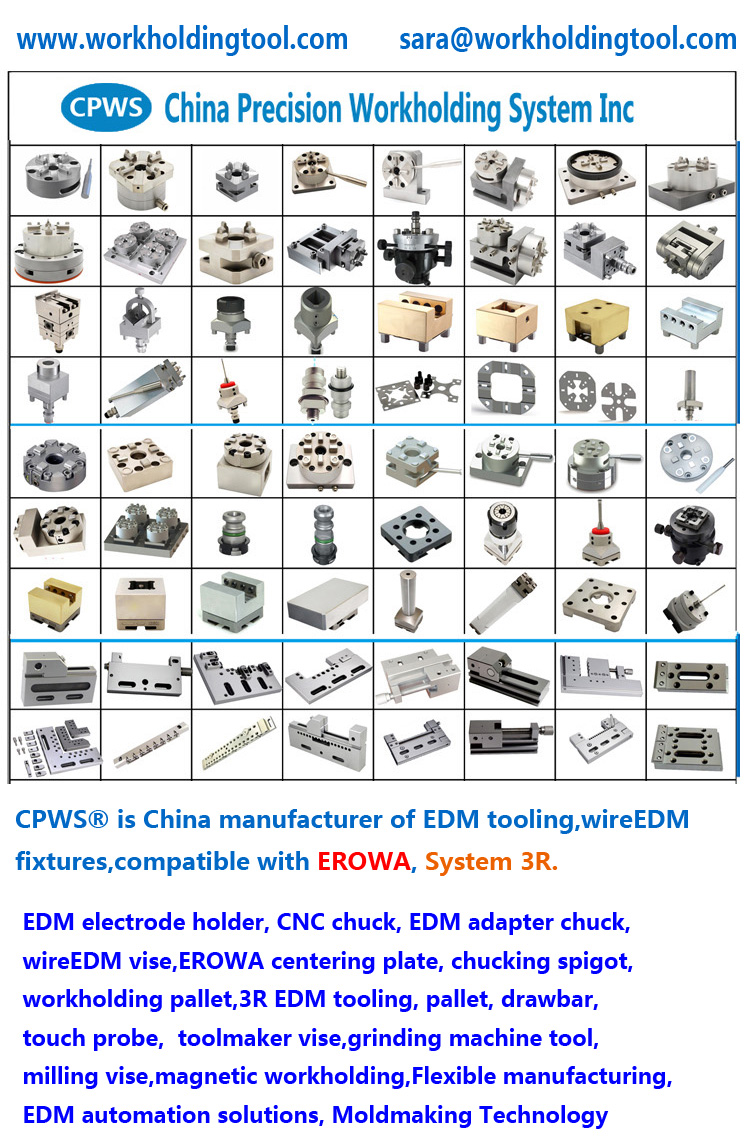

China Precision Workholding System Inc

CPWS makes compatible EROWA chuck,vise,electrode holder, centering plate,EDM,wireEDM workholding fixtures,

at lower cost,