Many tool makers look out across their shop floors and see too many of their machines sitting idle too much of the time. They also worry about how to bridge the skills gap that will be critical to the future of the business. And shops must deal with these challenges in the face of growing customer demands for shorter lead times, higher quality, and greater cost controls.

In the production world these kinds of pressures have led volume manufacturers to widely embrace automation. But how do you automate such a complicated process as building one-off dies and molds? Where would you begin? How far should you go? How would you build a plan to see it through?

It can be done, and a number of leading tool makers are moving in this direction already. Well-known machine tool builder Makino has been deeply immersed in process development for both mold making and automation for many years. So it comes as little surprise that they have a lot to say about how to bring these technologies together to create a more efficient mold or die shop. John Bradford is Makino’s manager of proposal engineering for standard pallet automation solutions. In that role he has helped a range of tool shops develop automation implementation strategies. What follows is Bradford’s advice on how to construct a practical path to tool shop automation.

The Plan

Automation can serve a mold or die shop in a variety of ways, and the first step to developing an action plan is to determine which objectives are most important to your shop. The most common reasons to automate include:

Makino’s Die/Mold Automation whitepaper takes a very practical look at the considerations of automating a tool shop.

Download Whitepaper.

Improve machine utilization – It’s costly to have expensive equipment sitting idle with needlessly long setups, inefficient workpiece handling, frequent cycle interruptions to change tools or other manual interventions, or just waiting too long for the next job.

Increase capacity – Solving these problems will increase capacity, bringing better ROI to your technology investments with more output per day. Capacity is stretched even further when shops learn to machine unattended over extended periods of time.

Improve quality – Automation forces a shop to bring greater consistency to their machining processes and, once that’s accomplished, is less prone to human error.

Reduce lead times – The efficiencies and process consistency brought on by tackling the above issues reduces the time it takes to machine a part and likely will reduce EDM requirements and bench time as well.

Better leverage skilled labor – The best use of skilled people is to integrate their knowledge into your machining processes rather than having them directly control those processes themselves. This too increases capacity and quality though in a different way.

Achieving any of these goals will increase a shop’s efficiency and lower overall costs. How far you take an automation project will depend on which are most consequential to the business.

The first step of any automation plan is to acquire a deep understanding of your existing shop practices. How do you create and validate part programs? How do you load, hold and locate workpieces? How do you manage cutting tools? That includes tasks such as establishing workpiece and cutting tool offsets, monitoring wear, and replacing tools or inserts. How do you validate quality?

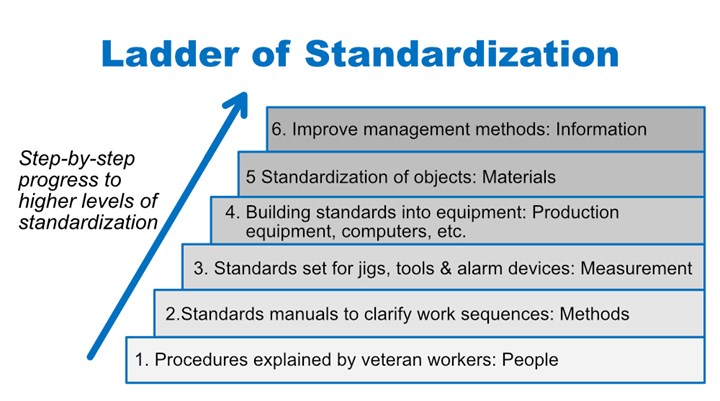

Standardizing all the stages of the manufacturing process enables automation of a tool shop.

All of these practices are hugely consequential to your ability to automate, and it will be necessary to standardize each to the extent that is practical. In many cases you will have to fundamentally change the way you go about them.

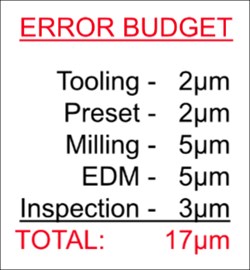

An error budget will define how accurate your total process can be.

It’s also important to establish an error budget based on the precision and repeatability of a variety of process variables such as tooling accuracy, preset values, the machining process itself, EDM and inspection. Similar to a tolerance stack in an assembly, it’s the combination of all these variables that will determine your ability to control accuracy across the entire machining process.

Most tool shops have never thought about process capabilities in quite this way and will find that they have a great deal of variability within each component of their total process, which they’ve been correcting through myriad manual interventions in the machining process. That won’t work in an automated environment. But once you understand current practice you can go to work standardizing each component of the toolmaking process. When these practices become more predictable, stable and reliable you can start to think about how to automate with proven methods to prepare for new jobs, machine without test cuts or manual in-process adjustments and finally to automatically move workpieces in an out of machines.

In this mode of operation, part programs will be fully validated and simulated in a virtual machine environment offline. Workpieces will be mounted on precision locating pallets before being brought to the machine. Workpiece materials and tools will be preset offline. Tool life will be predictable, and redundant tools will be loaded so worn tools can be changed automatically without stopping the machining cycle.

The Path to Automation

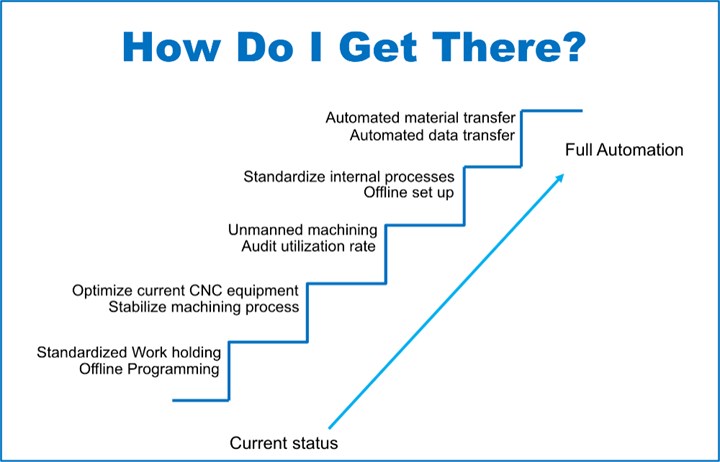

Most shops will realize large gains in efficiency just by getting the fundamentals right. But there is much more productivity to be gained by taking an automation project to the next level.

Achieving A Stable Machining Platform

The key to successful die-mold automation is the ability to maintain predictable and stable machining processes over time, particularly with die mold machining where materials are difficult, cycle times are long and mistakes can be costly. Simply, you need a predictable and repeatable machining platform to deliver the process consistency necessary to generate complicated 3D workpieces. Two critical and interrelated factors here are the inherent volumetric accuracy and thermal stability of the machine.

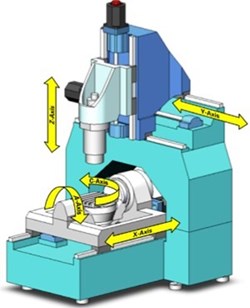

Symmetrical machine design is an important factor in mitigating the ill effects of thermal distortion. Also important is providing equal support across the entire axis travel ranges, as show in this rendering of Makino’s DA300 five-axis machining center.

Makino’s answer for this is to build machining centers with symmetrical designs that minimize thermal distortion and apply active thermal management systems to keep the machine thermally stable in the first place. The five-axis DA300 vertical machining center is a good example of how machine design is critical to achieving these objectives. A variety of factors combine to deliver high positioning accuracy (±0.000060″) including core-cooled, fine-pitch ballscrews with 0.05 micron scale feedback. The high-speed spindle provides consistent performance across the entire speed range enabling efficient roughing routines as well as accurately machining fine features with small tools. The spindle is also thermally controlled providing optimum performance over extended periods. The Pro 6 control includes a number of features such as Collision Safe Guard and SGI Smoothing that, along with the high speed capabilities and accuracy of the machine, enable the ability to safely generation of smooth, well blended surfaces that reduce requirements for post machining processes such as EDM and hand finishing.

Makino V5 VMC fit with Erowa automatic pallet system

Makino applies similar technology across a range of three-axis models including the F5 Pro 6 for hard milling , V22 for precision machining in difficult materials , V33i for extremely accurate high-speed machining and V56i for accurate high-speed machining of larger workpieces. Five-axis machines designed for die/mold machining include the DA300 designed for a wide range of materials and applications and the D200Z for ultra-high performance on very complex parts.

All of these machining centers are designed to easily integrate with workhandling automation. While Makino can design and build custom automation systems, a more practical and affordable approach is often to use standard automation components, including 3rd party equipment that is “preintegrated” with Makino machines. For example, these machining centers all are designed to integrate with Erowa’s standard robotic loading systems without any modifications other than the addition of standardized cell control software.

Where to Start

As for what to automate, Bradford recommends starting small and then expanding as you gain confidence in your capabilities.

In this electrode cell grapite blanks are automatically loaded into a Makino D200Z machining center, offloaded and stored, and then automatically loaded into a Makino (model) die sinker. All the workhandling is managed by an Erowa Robot Compact 80.

A good first process to automate is machining of graphite electrodes. It’s the lowest risk type of workpiece in a tool shop with a high potential return. Also, in-process variables such as tool wear are minimal. Next try automating your die sinker EDM. Standard workholding systems are available from suppliers such as Erowa and System 3R (GF Machining Solutions) that enable the ability to move an electrode from a machining center to sinker without having to reestablish location references. And there are standard robotic handling systems designed to do just that.

Then it’s time to move on to machining metal. Bradford suggests starting with aluminum and other softer materials where you can see how well you can hold tolerances in an automated environment and manage other process factors such as tool life. Once that’s under control you can move on to direct milling of hard materials where the machining is challenging, the geometry is complex and the ability to generate smooth surface finishes is critical. Here tool selection and tool life predictability are extremely important as well as optimizing feeds and speeds to deliver consistently reliable performance over long periods of time. You won’t machine as aggressively as you might on an operator tended machine, but the point is for everything to run smoothly when an operator isn’t there.

Adding an Erowa Robot Easy allows this Makino DA300 machining center to run unattended for significant periods of time.

The Human Factor

The most challenging aspect of introducing automation to a tool shop is usually affecting the cultural change necessary for shop employees to embrace a new way of working. For the skilled toolmaker who is accustomed to doing everything – from setup to tool management to adjusting machining parameters to inspection – a more automated approach will have a big impact on his job. Rather than one person controlling virtually all aspects of the machining process you will move to having dedicated areas of the shop for functions such as placing parts on pallets properly with work offsets established outside the machine or tool presetting with people who are skilled in those specific tasks.

Yet your most skilled toolmakers are precisely the people who need buy in to an automation project to make it successful. As Bradford puts it, “You need to establish a shared vision across the organization. That takes leadership and the full commitment of management in supporting the project.” He says the shops that do this well are effective at establishing their best people as the knowledge base of the organization who then become teachers and mentors for the rest of the team.

This can be hard for highly skilled people who have been doing their jobs in the same way for years. But it is also an opportunity for them to share their expertise across the entire organization which actually increases their influence in the company. There are major business benefits as well with the ability better leverage your best people’s knowledge and capture best practices that will be beneficial for years to come. To make it happen, though, management must make every effort to ensure that employees see it this way too.

While the ultimate in tool shop automation is lights out machining of cores and cavities, John Bradford is careful to point out that shouldn’t necessarily be everyone’s ultimate goal. “Some shops will find that getting halfway there provides the return they were looking for, and that further efforts to automate may not be worth the investments in time and technology,” he says. “There’s nothing wrong with that if they are meeting the initial goals they set out to achieve.”

For many shops, the move toward automation is already paying big dividends in getting more out of their substantial investments in technology and people. For die and mold makers, there surely will be more of this to come.

Go here for more information on Makino technology for Die/Mold Machining.

China Precision Workholding System Inc (CPWS)

CPWS was established in 2008 in China,specialized in designing and manufacturing of Precision Workholding

Fixtures,clamping tools for EDM,wireEDM,CNC milling,grinding machines. CPWS is 100% compatible with EROWA and

3R, Our Products include precision EDM electrode holders, ITS accessories like centering plates, chucking spigots, ITS

chucks, ITS measuring tools,sensor,guaging pin, 3R holders, pallets,drawbars,power chucks,zeropoint system,ER collet

chuck,guide bush, wireEDM fixtures and vise. Our Manufacturing base in GuangDong, has offices in

GuangZhou,ShenZhen, JiangSu, HongKong, and has exported for 10 years to Southest Asia, Europe, South Korea,

Russia, USA, Canada,Mexico, Brazil, Australia. CPWS is also agent for other tooling makers in China,help other local

tool makers to sale and export, and CPWS also offers one-stop sourcing service for overseas importer, such as

logistics, warehousing, contract, Interpretation, to reduce overseas customers import cost. CPWS also accept OEM

work, customer can send us a drawing if the order quantity is reasonable to make a production.

CPWS always pursues to produce high quality products at the lowest price,fast delivery,best service.

We are looking forward to your kind cooperation, and we would highly appreciate any feedback regarding our products quality,service.

www.workholdingtool.com

sara@workholdingtool.com